How to Prevent Liquid Spills through using Proactive Prevention Technology

How can Technology Prevent Liquid Spills?

One stat uncovered by research from the Health and Safety Executive (HSE) was that 71% trips and Slips are avoidable. Slips and trips on the face of it may not sound too serious and may be viewed as just one of the many hazards that we as humans encounter on a daily basis, along with crossing the road. However, dig a little deeper and related stats become rather scary.

Noteworthy is that 50% of all claims made against retailers are for slip trip and fall cases. The cost of trips and slips for US businesses amounts to a staggering $11bn per annum. In the UK, stats published by the HSE show that the cost to society of slips, trips and falls is around £800M. They are also the second highest single cause of workplace injuries and 22% of them lead to over a month off work. In short, big numbers that form huge, yet avoidable, cost centres within respective businesses.

Preventing Liquid Spills - how are they avoidable?

Humans unfortunately are ‘not’ good at following strict rules, if we were we would ‘not’ need a police force, yet every nation on the planet has one. But why? There is a natural human tendency to rationalise short-cuts, particularly when operating under pressure, these shortcuts are hardwired into cognition and are referred to as ‘heuristics’ by behavioural scientists.

Confirmation bias is a particularly powerful heuristic. It is an inbuilt tendency to search for, interpret, favour, and recall information in a way that confirms or supports one's prior beliefs. For example, consider a scenario wherein a member of staff in a retail store is under pressure to re-stock shelves and in the process of doing so notices a liquid spill of some form. Understandably, they may continue stocking shelves until finished, before notifying anyone of the spillage.

Interestingly, if they have done this before and nothing bad happened as a result of delayed reporting, the lack of bad outcomes can actually reinforce the ‘rightness’ of trusting past success instead of objectively assessing related risks; the immediate danger that the spill represents from a health and safety perspective. Nobel laureate Richard Feynman compared the practice to Russian Roulette:

Confirmation bias is an extremely dangerous heuristic, since through it little weight is placed upon disconfirming information. Yet, with every roll of the dice, or pulling of the trigger, the probability of something really bad happening, as we move forward in time, actually increases. As we can see, this heuristic produces an extremely poor perception of risk, which was also 1 of 15 individual human behavioural factors highlighted by research from the HSE that contributed towards trip and slip incidents.

Liquid Spill Prevention through Technology

Training can help, but as most Health & Safety professionals will testify, it leaves them locked into a continuous battle with traits hardwired into cognition. We then have the fact that is it difficult to spot clear liquids on shiny floors, along with another significant contributory factor highlighted by the HSE in trip and slip cases, which was that of customers dropping items then failing to report them.

To cover-off these risks requires a twofold approach. Namely, the need for ongoing training to continually reinforce the need for H&S procedures to be followed and for floor walkers so that they can spot clear liquid spills, for example from leaking fridges, condensation, hand sanitiser dispensers, or whatever. However, this still leaves businesses reliant upon those that can become distracted, and when they do they deliver poor risk assessment, which provides rather an unreliable reporting system for preventing incidents related to liquid spills.

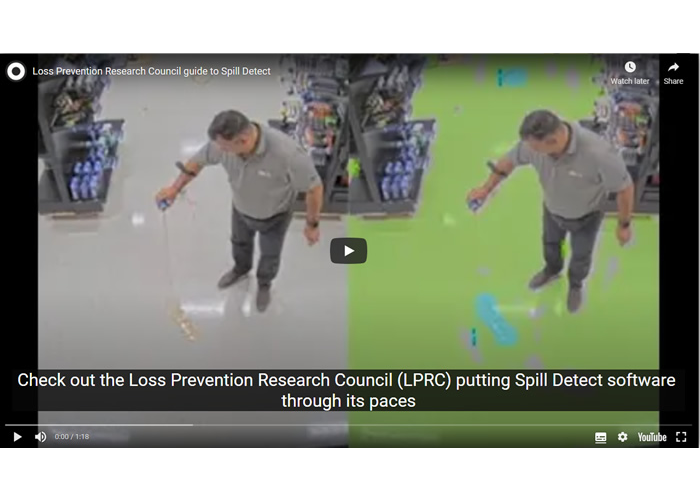

So, why do we use humans? Eyes. However, and quite interestingly so, most retailers have a large amount of eyes fitted throughout their stores in the form of CCTV cameras, which capture an incredible amount of highly valuable data that generally remains unused. Through a world first in clear liquid detection, businesses can now remove humans from the reporting loop, release the latent value of the data they capture with their existing CCTV networks and benefit from technology that is programmed to follow strict rules with Spill Detect.

This patent pending technology requires minimal setup and can recognise clear liquid spills from up to 100ft through using existing CCTV infrastructure. Notifications can be provided via a portal, or through announcements, email, SMS or other integrations, so that they fit perfectly within the specific environment of any given user. Spill Detect even displays an image along with a 30 second video clip prior to the spill and as standard, a full audit trail of the spill and clean-up is also integrated into the system for KPI monitoring.

The Business Case for Liquid Spill Prevention

Companies are now under increasing corporate and social responsibility to provide high levels of occupational health and safety for their employees, along with a safe and enjoyable shopping experience for their customers. Are these additional cost centres, or is it just good business practice to provide them?

Interestingly, during a recent conversation with high level asset protection and health and safety professionals from a large US retailer, they saw clear commercial advantages in differentiating themselves through a mission to ‘become the safest place to work and shop’. Can this actually provide a source of competitive advantage, and is it sustainable? The literature, as supported by anecdotal evidence, suggests that the ability of a firm to achieve a source of sustainable competitive advantage ultimately pivots around its capability to correctly combine technology with its human capital. For example, using technology to improve levels of individual decision making at the micro-level, and developing this as an internal strength, as it adds value by removing cost.

This process may to some extent become inimitable, particularly if a firm develops specific infrastructure to support dedicated information flows with the aim of improving its internal knowledge base, particularly when viewing knowledge as a strategic resource and behavioural interaction with technology as a competitive advantage that develops over time. This cannot be easily imitated and becomes a ‘core competence’. Anecdotal evidence also suggests that this produces a rare entity, which emerges in the form of a whole system of knowledge management. An outcome that improves operational efficiency and productivity - Spill Detect can help to set you on this path through delivering an ROI in less than 3 months.

Why not explore what Spill Detect can do for your organisation? Simply Contact us now for a demo.